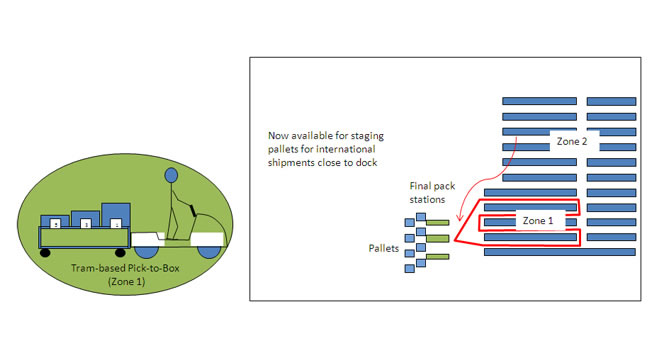

Total restructuring and standardization of operational systems at North American and European Distribution Centers. The effort included zone picking, deployment of inexpensive trams following short pick routes, relocation of inventory to enhance pick density, implementation of direct pick-to-box or pick-to-pallet to avoid material re-handling, enhancement of IT systems to speed human interfacing and increase speed and accuracy of transactions.

Domestic Shipping process improvements

- Project timeline: 28 weeks

- Project Cost: $301,000

- Project annualized savings: $924,000

- Return on Investment: 3.1

Pick Process Improvements

- Tuggers instead of push carts

- Inventory zone by pick frequency

- Consolidated and sorted pick lists

- Short , simple pick routes

- Direct pick-to-box

Future State

Future State

- Two zone pick-to-box system, analogous to NADC Project 1

- Pack stations reduced from 6 to 3 (boxing is no longer required) and moved close to racks. Tape machine installed

- Pallets staged alongside an accumulator conveyor for quick staging

- Picking operator packs his/her own orders and holds responsibility for correct counts

- Unnecessary verification step eliminated

Results

- Reduced required staffing by 37%

- Eliminated 6 computer stations

- Increased lines per hour by 40%